Duplex steel

F53 (SAF2507) corresponding domestic and international grades:

GB | UNS | BS EN | JIS | |

F53(SAF2507) | 00Cr25Ni7Mo4N | S32750 | 1.4410 |

Minimum mechanical performance parameters

Tensile strength | Yield strength | Elongation rate |

800 | 550 | 15 |

Chemical element (wt%)

C | Mn | P | S | Si | Ni | Cr | Mo | Cu | N | Fe | |

0.03Max | 1.20Max | 0.035 Max | 0.020 Max | 0.80 Max | 6.0 – 8.0 | 24.0-26.0 | 3.0-5.0 | 0.50Max | 0.24-0.32 | Balance | |

Note: Pitting corrosion resistance equivalent value(PRE=Cr%+3.3*Mo%+16*N%)≥40 | |||||||||||

Heat treatment

The heat treatment of 2507 should avoid the range of 475℃ and 950℃. To select an appropriate heat treatment system, rapid cooling is necessary. It is crucial to control the austenite phase and ferrite phase at around 50%. After cold working, a heat treatment temperature of 1025℃-1120℃ should be adopted, which can be used for stress relief and solution treatment of the material. Within the heat treatment temperature range, as the temperature rises and the time extends, the ferrite content will gradually increase and the grains will gradually coarser. After heat treatment of materials, rapid cooling should be carried out. Generally, water quenching or rapid rapid air cooling can be selected to avoid the precipitation of harmful phases due to insufficient cooling during the cooling process.

Characteristics

S32750 is also known as super duplex stainless steel. Its high chromium and molybdenum content endows it with strong resistance to overall corrosion from organic acids such as formic acid and acetic acid. SAF2507 alloy also has strong corrosion resistance to inorganic acids, especially those containing chlorides.

Compared with 904L,SAF2507 has stronger corrosion resistance to diluted sulfuric acid mixed with chloride ions. 904L is an austenitic alloy specifically designed for resistance to pure sulfuric acid corrosion.

Grade TP316L cannot be used in hydrochloric acid environments as it may suffer from local or overall corrosion. SAF2507 can be used in diluted hydrochloric acid environments and has strong resistance to spot damage and crack corrosion.

The lower carbon content of SAF 2507 significantly reduces the risk of intergranular carbide precipitation during heat treatment. Therefore, this alloy has a strong ability to resist intergranular corrosion related to carbides.

Stress corrosion cracking

The compound structure of SAF 2507 endows it with a strong ability to resist stress corrosion cracking.

Due to its higher alloy content, the corrosion resistance and strength of SAF 2507 are both superior to those of S32205.

Purpose

● Petroleum and natural gas industry equipment

● Offshore platforms, heat exchangers, underwater equipment, fire-fighting equipment

● Chemical processing industry, vessel and pipe industry

● Desalination plants, high-pressure RO plants and submarine pipelines

● Mechanical components (high-strength, corrosion-resistant components)

● FGD systems for the energy industry, industrial scrubbing systems, and absorption towers

Introduction to S32760 material and Application scenarios

#### 1. Overview

S32760 (also known as F55, 1.4501 or Zeron 100) is a super duplex stainless steel, renowned for its outstanding corrosion resistance, high strength and excellent mechanical properties. It achieves outstanding performance in extreme environments through an optimized proportion of alloying elements such as chromium, molybdenum, nickel and nitrogen in a high proportion. S32760 features a dual-phase structure of both austenite and ferrite, achieving a good balance among corrosion resistance, strength and toughness. It is widely used in Marine engineering, petrochemicals, energy and other fields.

| Performance index | Unit | Minimum value |

| Yield strength Rp0.2 | MPa | ≥550 |

| Tensile strength Rm | MPa | ≥750 |

| Elongation rate A | % | ≥25 |

Hardness (HB) | - | ≥270 |

---

| Performance index | Unit | Numerical value |

| Density | g/cm³ | 8.0 |

| Melting point | ℃ | 1400-1450 |

| Specific heat capacity | J/kg·K | 460 |

| Resistivity | μΩ·cm | 90.0 |

| Thermal conductivity | W/m·K | 12.8 |

#### 2. Chemical composition and physical properties

The chemical composition of S32760 mainly includes:

- Chromium (Cr) : 24%-26%, providing excellent oxidation resistance and corrosion resistance.

- ** Nickel (Ni) ** : 6%-8%, enhancing toughness and high-temperature resistance.

- ** Molybdenum (Mo) ** : 3%-4%, significantly enhancing resistance to pitting and crevice corrosion.

- ** Nitrogen (N) ** : 0.2%-0.3%, enhancing strength and corrosion resistance.

- Copper (Cu) : 0.5%-1.0%, further enhancing the resistance to non-oxidizing acid corrosion.

Its physical properties include:

- ** Density ** : 7.8 g/cm³.

- Melting point: 1320-1400℃.

- ** Coefficient of thermal expansion ** : 17.2×10⁻⁶/K, good dimensional stability.

---

#### 3. Mechanical properties and corrosion resistance

S32760 performs exceptionally well in terms of mechanical properties and corrosion resistance.

** Mechanical properties ** :

- ** Tensile strength ** : ≥750 MPa.

- Yield strength: ≥550 MPa.

- ** Elongation ** : ≥25%.

- Hardness: HB 280-320.

2. ** Corrosion resistance **

- ** Resistance to pitting and crevice corrosion ** : The PREN (pitting equivalent number) is as high as 40-45, capable of resisting corrosion in high-chloride environments.

- ** Resistance to Stress corrosion cracking ** : It performs well in media containing chloride ions and acids, and is suitable for Marine and chemical environments.

- ** Acid and alkali resistance ** : It can resist strong corrosive media such as sulfuric acid, hydrochloric acid, and hydrofluoric acid.

---

#### 4. Processing and heat treatment

S32760 has excellent processing performance:

- ** Hot Working ** : It is recommended to carry out hot forming within the range of 1000℃-1200℃, and the final temperature should be higher than 900℃.

- ** Cold working ** : Strength and surface quality can be enhanced through processes such as cold rolling and cold drawing.

- ** Welding ** : Applicable to welding methods such as TIG and MIG, no heat treatment is required after welding, and the weld quality is high.

Heat treatment processes include:

- ** Solution treatment ** : Heat to 1050℃-1150℃, then rapidly cool to obtain a single-phase austenite structure.

---

#### 5. Application scenarios

S32760 has been widely applied in multiple fields due to its outstanding performance:

"Marine Engineering

It is used in seawater desalination equipment, offshore platforms, submarine pipelines, etc., and can resist seawater corrosion and high-pressure environments.

2. ** Petroleum and Gas Industry **

It is suitable for oil well casings, oil pipelines, storage tanks, etc., and can withstand high chloride and hydrogen sulfide environments.

3. "Chemical Industry

It is used for manufacturing reactors, heat exchangers, distillation towers and other equipment, and can withstand strong acids, strong alkalis and high-temperature environments.

4. Energy Industry

In nuclear power plants and thermal power plants, it is used for heat exchangers, boiler components, etc., to ensure stable operation under high-temperature and high-pressure environments.

5. "Food and Pharmaceutical Industry

It is used for manufacturing food processing equipment, storage tanks and pharmaceutical equipment, meeting hygiene standards and ensuring safety and durability.

6. Environmental Protection and Sewage Treatment

It is used in wastewater treatment equipment, biological reactors, etc., and can resist the erosion of corrosive media.

---

#### 6. Summary

S32760 is a high-performance super duplex stainless steel. With its excellent corrosion resistance, high strength and good processing performance, it plays an important role in Marine engineering, petrochemicals, energy and other fields. Its wide range of application fields and outstanding performance make it an ideal material in harsh industrial environments. With the advancement of technology, the application prospects of S32760 will further expand, providing more reliable support for industrial development.

Corresponding domestic and international grades of 2205:

GB | UNS | BS EN | |

2205 | 00Cr22Ni5Mo3N | S32205/S31803 | 1.4462 |

Minimum mechanical performance parameters

Minimum mechanical performance parameters Rm N/mm2 | Yield strength RP0.2N/mm2 | Elongation rate % |

655 | 293 | 25 |

Chemical element (wt%)

C | Mn | P | S | Si | Ni | Cr | Fe | Mo | N |

0.03 Max | 2.00 Max | 0.03 Max. | 0.02 Max. | 1.00 Max. | 4.50 - 6.50 | 22.0 - 23.0 | Balance | 3.00 - 3.50 | 0.14 - 0.20 |

Heat treatment

Alloy 2205 should be annealed at a minimum temperature of 1038 ° C (1900°F), followed by rapid cooling and water quenching. This treatment is applied to solution annealing and stress relief. Stress relief treatment, if carried out at a temperature lower than 1038 ° C (1900°F), is prone to cause the precipitation of harmful metallic or non-metallic phases.

Characteristics

Organizational characteristics

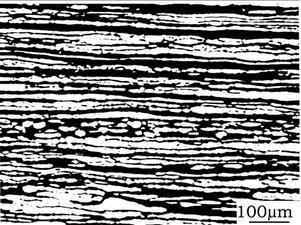

At room temperature, the solid solution of duplex stainless steel contains approximately half austenite and half ferrite (the ferrite content of duplex stainless steel 2205 should be 30% to 55%, with a typical value of around 45%), and it has the characteristics of a two-phase structure, as shown in Figure 1. It retains the characteristics of ferritic stainless steel, such as high thermal conductivity, low linear expansion coefficient, resistance to pitting corrosion, crevice corrosion and chloride stress corrosion. It also has the advantages of austenitic stainless steel, such as good toughness, low brittle transition temperature, resistance to intergranular corrosion, and good mechanical and weldability properties.

Figure 1 Typical microstructure of 2205DSS plates

Performance characteristics

The outstanding performance is its high yield strength and resistance to stress corrosion.

The yield strength of duplex stainless steel is nearly twice that of austenitic stainless steel. Under the same pressure grade conditions, it can save materials. The linear thermal expansion coefficient is lower than that of austenitic stainless steel and close to that of low-carbon steel. It makes the connection between duplex stainless steel and carbon steel more appropriate, which has great engineering significance. However, its high strength makes its plasticity in forging and cold stamping less than that of austenitic stainless steel, increasing the difficulty of processing and manufacturing, and resulting in a relatively low yield rate.

Hot crack

The sensitivity to hot cracking is much lower than that of austenitic stainless steel. This is because the nickel content is not high, and there are very few impurities that can easily form low-melting-point eutectics, making it difficult to produce a low-melting-point liquid film. In addition, there is no risk of the grains growing rapidly at high temperatures.

Proportional requirement

The mechanical properties and corrosion resistance of duplex stainless steel welded joints depend on whether the welded joints can maintain an appropriate phase ratio. Therefore, welding is carried out around how to ensure its duplex structure. When the ferrite and austenite volumes are each close to 50%, the performance is good and close to that of the base material. Altering this proportional relationship will lead to a decline in the corrosion resistance and mechanical properties (especially toughness) of the duplex stainless steel welded joint. The optimal ferrite content of duplex stainless steel 2205 is 45%. Too low ferrite content (<25%) will lead to a decrease in strength and resistance to stress corrosion cracking. Excessive ferrite content (>75%) can also be detrimental to corrosion resistance and reduce impact toughness.

Proportional influencing factors

The equilibrium relationship between ferrite and austenite in the welded joint is affected not only by the content of alloying elements in the steel, but also by the filler metal, the welding heat cycle and the shielding gas.

The influence of alloying elements

According to research and a large number of experiments, it has been found that the presence of nitrogen in the base material is very important. Nitrogen plays an important role in ensuring the formation of a sufficient amount of austenite in the weld metal and the heat-affected zone after welding. Nitrogen, like nickel, is an element that forms and expands austenite. However, nitrogen has a much greater ability than nickel. At high temperatures, nitrogen has a greater ability to stabilize austenite than nickel, which can prevent the formation of single-phase ferrite after welding and stop the precipitation of harmful metal phases.

Due to the effect of the welding thermal cycle, when the composition of the filler metal in self-melting welding is the same as that of the base metal, the amount of ferrite in the weld metal increases sharply, and even pure ferrite structure appears. In order to suppress the excessive increase of ferrite in the weld seam, the use of weld metal with austenite dominance is the welding trend of duplex stainless steel. Generally, two approaches are adopted: adding nickel to the welding materials or adding nitrogen. Generally, the nickel content is 2% to 4% higher than that of the base metal. For instance, the nickel content of 2205 filler metal is as high as 8% to 10%. Using nitrogen-containing fillers is more effective than only increasing nickel fillers. Both elements can increase the proportion of the austenite phase and stabilize it. However, adding nitrogen not only delays the precipitation of the intermetallic phase but also enhances the strength and corrosion resistance of the weld metal.

2. Filling materials

At present, the filling materials are generally made by increasing the nickel content and then adding nitrogen equivalent to the content of the base material.

For duplex stainless steel 2205, the Sandvik22.8.3.L(ER2209) wire is selected for tungsten inert gas welding, and the Avesta2205AC/DC electrode is used for electrode arc welding, which meets the requirements for welding materials. The characteristics of duplex stainless steel 2205 and welding materials in terms of alloying elements provide a certain range for the selection of welding process parameters, that is, the energy of the welding line, which is very beneficial for welding.

3. The influence of thermal cycling

The most prominent feature of duplex stainless steel welding is that the welding heat cycle has an impact on the microstructure within the welded joint. Both the weld seam and the heat-affected zone will undergo phase transformation, which has a significant influence on the performance of the welded joint. Therefore, multi-layer and multi-pass welding is beneficial. The subsequent weld bead has a heat treatment effect on the previous weld bead. The ferrite in the weld metal is further transformed into austenite, forming a two-phase structure dominated by austenite. The austenite phase in the heat-affected zone adjacent to the weld seam also increases accordingly, and it can refine the ferrite grains, reducing the precipitation of carbides and nitrides from within the grains and at the grain boundaries, thereby significantly improving the microstructure and properties of the entire welded joint. It is precisely due to the influence of the welding thermal cycle that when welding duplex stainless steel, the weld bead in contact with the medium should be welded first, which is exactly the opposite of the welding sequence requirement for austenitic stainless steel.

Application

Its application in industry for low cost and high manufacturability:

*Heat exchanger

*Ship platinum

*Petroleum gas industry

*Chemical engineering