About Us Publication download >>

Tanell is a branch company fully held by Jiawei Group, the flagship brand of the Group. It is located in the high-tech industrial base of Wenzhou City------Binhai park. It is a local manufacturer who strives to build a storage-type operating mode.

Products we focus on: socket-welding pipe fittings, threaded pipe fittings,Welded pipe fittings, flanges, valves and stainless steel pipes.

Our special alloys:

Stainless steel:304/304H、TP304L、TP316L、310S、TP347 / TP347H、 TP321/TP321H、S31254 / 254MO、 904L and 317L

Duplex stainless steel:S31803/S32205 and S32750/S32760

Nickel alloys:Monel 500、Monel 400、Inconel800H、Inconel625、Incoloy825、Hastelloy C276、Incoloy 600 and Alloy 20 (UNS NO8020)

With over 25 years of procurement and distribution experience, the Tanell staff can provide your company with a wide range of value-added services. Our goal is to provide the best product at the best price. We can offer custom-made products for our customers. If you need to purchase special stainless products, we can provide products that conform to the ISO 9001 standards and our professional metallurgy technology can always help you make the right choice.

Tanell has the total assets of nearly 50 million Yuan, and more than 150 staffs (15% technical personnel) with a factory of over 40,000 ㎡. It is located Longwan District, Wenzhou City, the center of valve industry in Binhai Park.

Tanell is specialized in manufacture in order to build a storage-type sales mode. Meanwhile, storage of raw materials is up to 1500 tons (among which the storage of special material alloys is 300 tons), and the storage of semi-finished and finished products are 80 tons. We believe that the finished product storage of new special materials can realize quantitative and normalized like TP304.

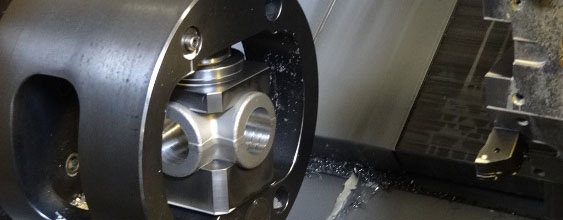

Production equipment

Tanell is a modern factory with high mechanization. It owns CNC brand sawing machine, bar cutoff machine, strong friction press (1000T-3000T), special CNC lathe, numerical control drilling machine, powerful annealing furnace, advanced ball blast and acid pickling and paralysis facilities. We made such a big investment in order to provide our customers with more perfect alloy products.

Inspection equipment

Based on the ISO 9001-2008 quality management system, Tanell introduced the SPECTRO MAXx, Niton XL2, supersonic thickness gauge, Feritscope FMP30, universal mechanics testing machine, impact testing machine, non-destruction test (ultrasound and liquid permeation), upright metallurgical microscope, stero microscope, analytical balance, and durometer, accompanied with internal control system customized by Kingdee K3. Each product owns the indent number, heat number and lot number. The process card records the whole production, featured by the testing and data recorded in every production link.

Application field

Our products are widely applied in sectors of papermaking, shipbuilding, petrochemical industry, electric power, bio-engineering, natural gas, sewage treatment, construction, medicine, foodstuffs (dairy products) and others.

Tanell is located in the most economically dynamic city—Wenzhou. It can utilize the rich local resources so as to meet the demands of China and Asia for piping system, and expand the products to the market of Europe and Ameica.

▶ Power plant ▶ Petroleum,natural gas and petrochemical

▶ Nuclear power plant ▶ Environmental protection

▶ Shipbuilding ▶ Chemical ▶ Papermaking ▶ Water

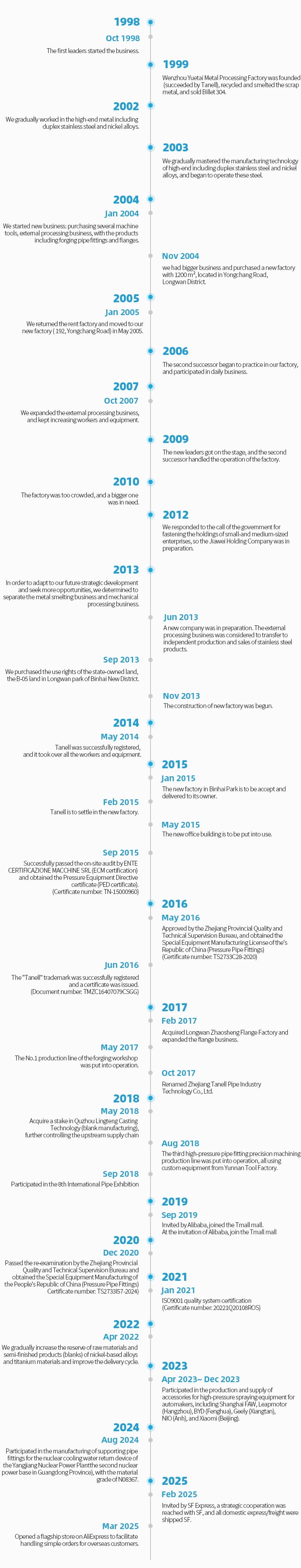

History of Development

Tanell developed from a domestic workshop to a modern factory, and its growth actually reflects the general development of small-and medium-sized enterprises. We will inherit the competitive strengths from our elder generation and continuously promote the great development of Tanell towards a better future. Now is our time.